Introduction:

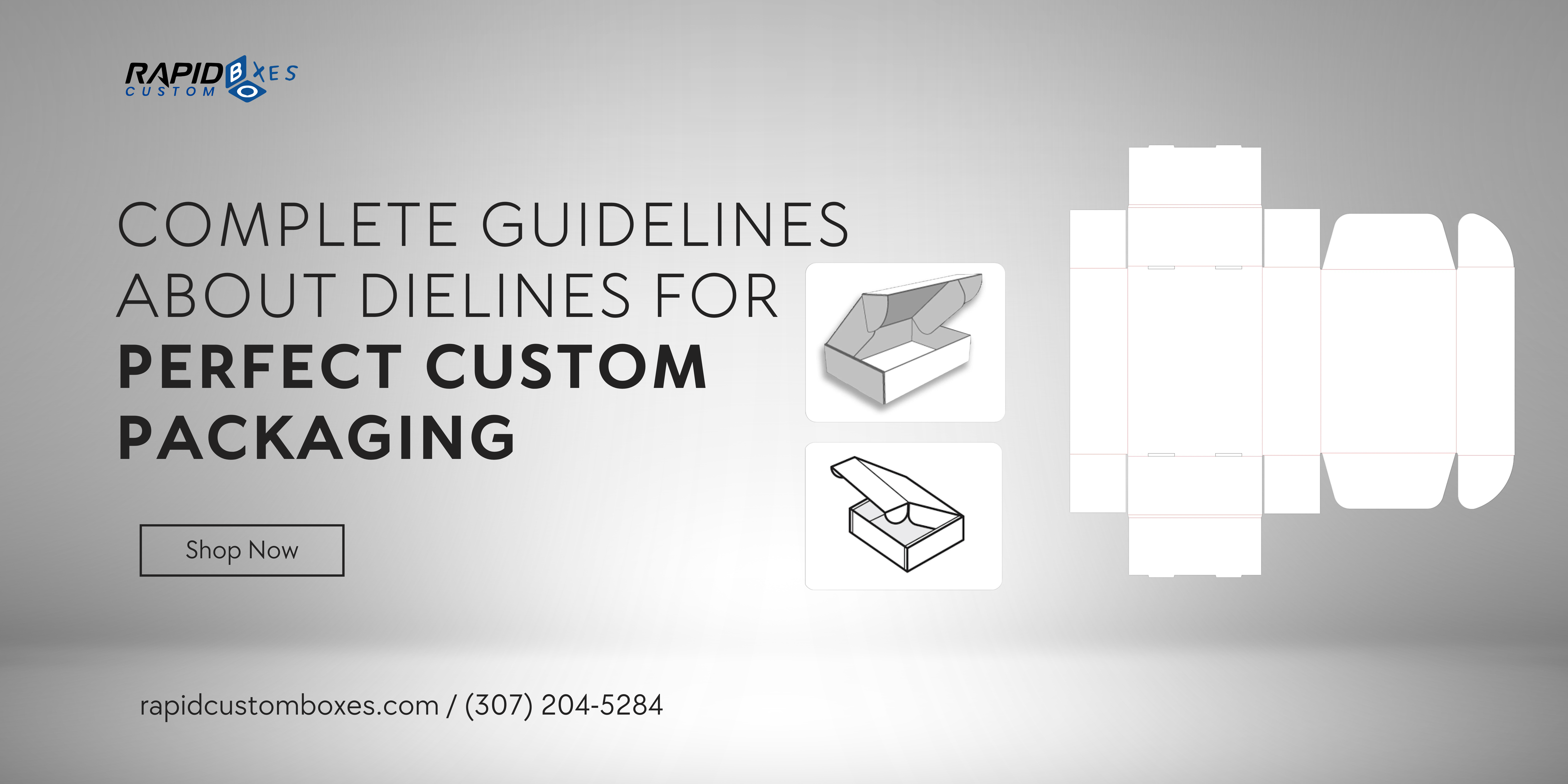

Dieline has a crucial role in designing custom packaging boxes according to the specifications of various products. They serve as a blueprint for having accuracy in the final packaging in terms of design, shapes, style, etc. In order to highlight your products in retail stores, businesses need perfect dielines for their packaging solutions.

For an ideal box that showcases your brand name and product features attractively, understanding dielines is a must. Here, we will provide all the essential information, including its standard components for in-depth knowledge.

What is a Dieline?

A decline can be described as a diagram or a template that showcases all the folds and cut lines of material to turn it into the desired box shape and style. These blueprints help to have accurate layouts for various packaging, including boxes, folders, envelopes, etc.

Components of a Dieline

This blueprint for designing is composed of the following elements:

Cut Lines

These lines are represented by the solid lines indicating where the packaging sheets need to be cut to turn into a box shape.

Fold Lines

These are dashed lines that showcase where the material sheets need to be folded for accurate assembly of the flattened packaging into a box shape.

Perforation Lines

These are dotted lines showcasing where the sheets are perforated for smooth tearing.

Cut lines, fold lines, and perforation lines are the most common components of a dieline. After that, some packaging boxes have other elements, too, depending on their aesthetic and functional features. So, other elements that a dieline can have are:

Bleed Areas

These are extended spots from the cut lines. They ensure that the printed design covers the edges of the material sheets without leaving any blank spots. Bleed areas help avoid white edges after cutting large sheets of packaging materials.

Margins

These are the safety spots on the packaging surface where there should be no design pattern or logo.

Glue Flaps

These are specific spots on the material surface where you need to apply any sort of adhesive. Such marks are common on a packaging dieline and critical for having a perfect box shape.

Score Lines

These marks showcase where the material sheets need to be scored for smooth and accurate folding.

This involved partial cutting or creasing for bending.

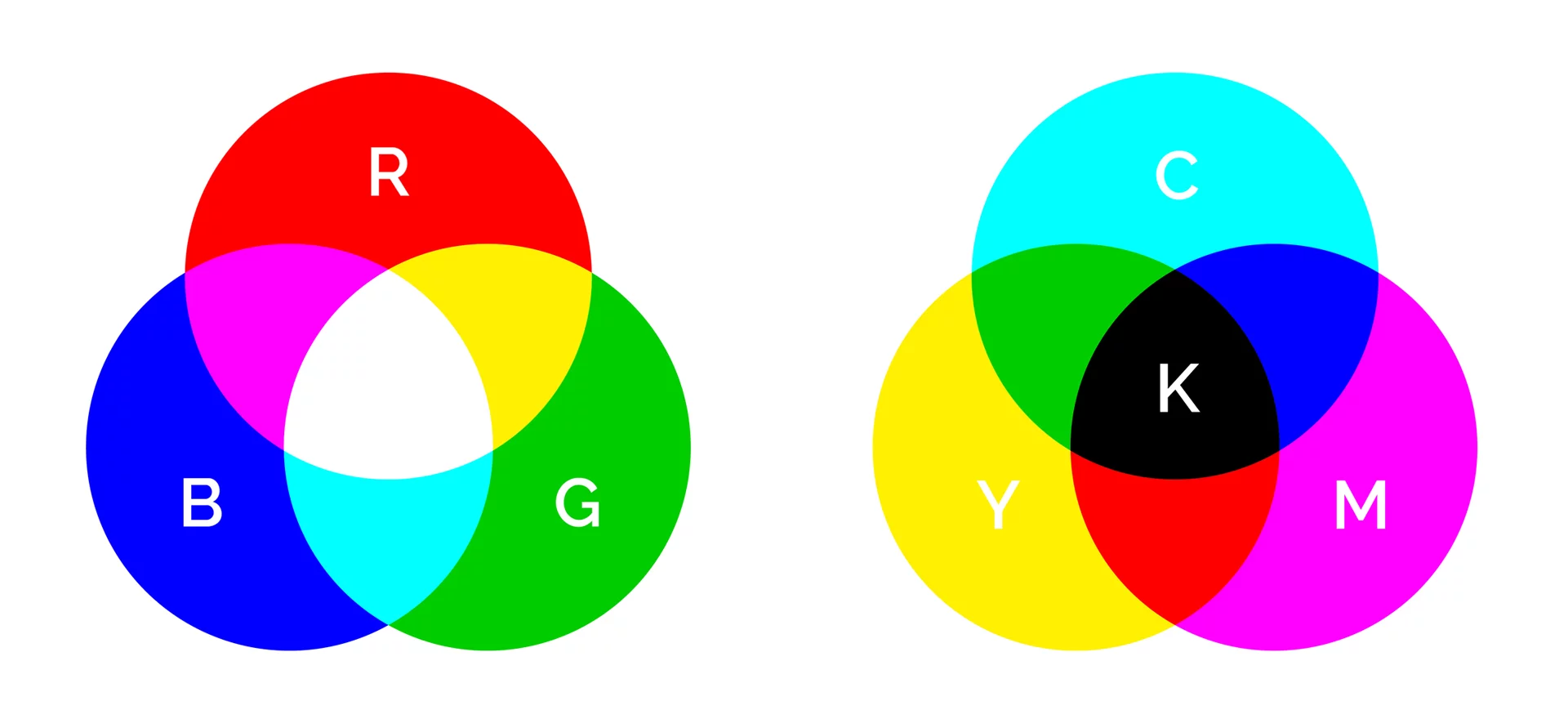

Registration Marks

These marks are useful for aligning the graphics and color schemes. The correct alignment of different printing plates helps produce accurate design prints without discrepancies.

Panel Dimensions and Labels

These marks give you an idea of the front, back, and bottom sides of the packaging. In the flattened packaging, they educate about the various dimensions of each element of dieline

Factors behind Successful Custom Box Designing

There are various factors that businesses need to understand to ensure they get perfect packaging for brand recognition.

Accurate Dimensions

Always provide accurate size dimensions, such as height, width, and length, before the conceptualization stage. These measurements determine the overall box shape.

Suitable Material Selection

The dieline of cardboard is different from corrugated fiberboard. The difference in the thickness and flexibility of various packaging materials also define your dieline accordingly. Some materials are easier to fold than others. Likewise, having intricate design patterns or simple ones depends on the material surface. So, you need to choose suitable materials that are flexible enough to meet your specific design requirements.

Prototypes for Testing

Dielines are digital blueprints and not physical samples, so there is still a chance of any discrepancy. Instead of relying on them completely, businesses need to start with prototypes before mass production of boxes based on any dieline. Check out all the aesthetical and functional features by getting samples in small quantities.

FAQs

Q: What are the primary objectives of a dieline?

The following are the basic purposes of using a dieline:

- Getting a layout for multiple marketing elements of custom boxes, including the logo and design patterns.

- Avoiding maximum manufacturing issues by getting an authentic layout before actual production.

Q: How do packaging designers make a dieline?

Designers with Adobe Illustrator make a dieline defining the cut lines, fold lines, etc. They set the document color mode to CMYK.

Bottom Line

A dieline serves as a blueprint for having custom boxes according to the specific product requirements. When businesses focus more on having accurate blueprints, the result will provide 100 satisfactory results.

Remember to choose only a reliable packaging supplier to get high-quality custom packaging with a perfect dieline. Rapid Custom Boxes is a professional platform that serves personalized solutions to its customers. It is highly reliable in having dielines according to your provided design elements, styles, shape dimensions, etc.